Our team of expertly skilled professionals are available for an obligation-free consult, please contact us to request a time. You can also use our free online project calculator to estimate your cost.

We can work with your budget to deliver a project that meets your needs, whether it be with professional installation by our experts, or a complimentary installation demonstration to help you with DIY installation.

We also offer free delivery within a 30-kilometre radius of our Gold Coast premises.

1. Estimate your cost with our online calculator.

2. Book your free consultation.

3. Schedule your complimentary measurement.

4. Receive your samples and information kit.

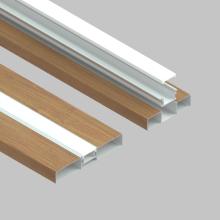

Aluminium is one of the strongest and lightest materials favoured in architecture.Distinguished by its incredible resistance and durability, it is the ideal material for our natural wood alternatives, designed specifically to withstand the harsh Australian climate.

Our patented AEZCLADD products have passed wind load and combustibility tests and are suitable for use in commercial and residential projects.They are lightweight and easy to install, with no experience required.

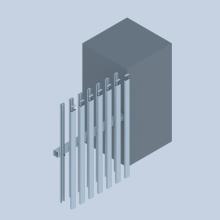

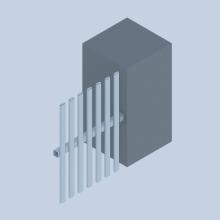

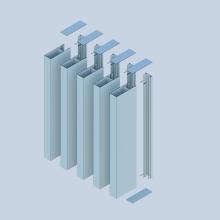

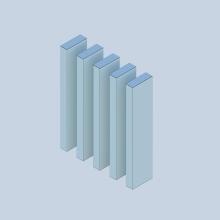

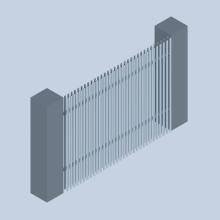

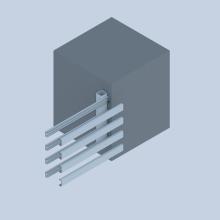

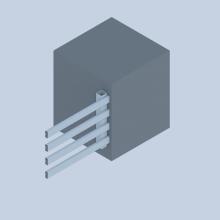

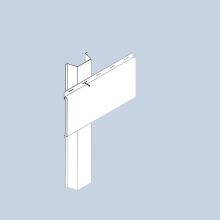

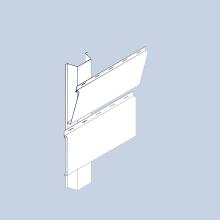

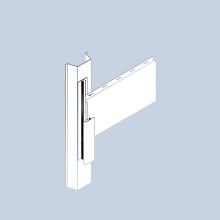

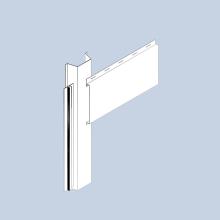

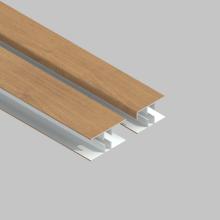

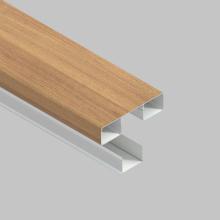

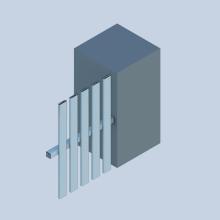

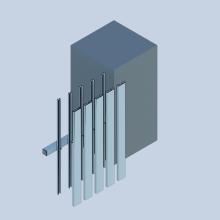

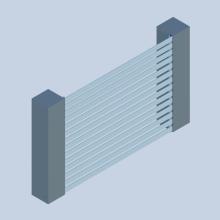

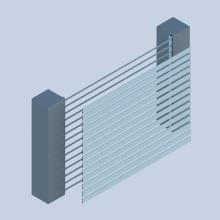

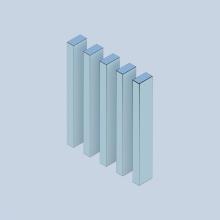

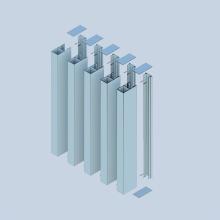

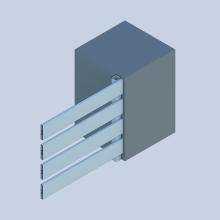

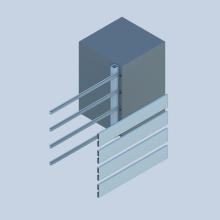

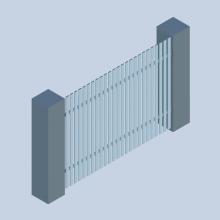

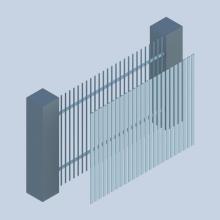

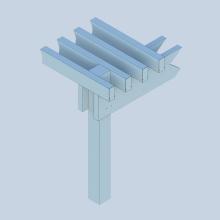

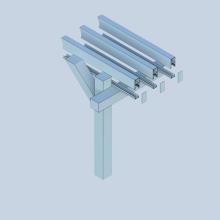

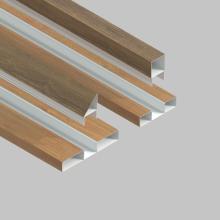

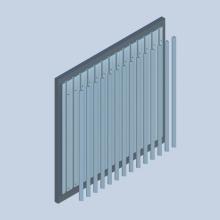

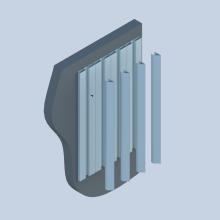

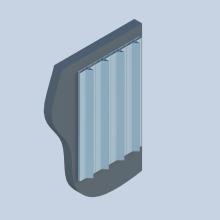

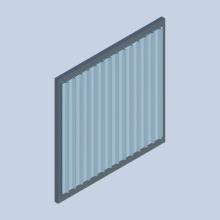

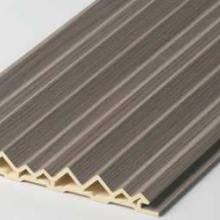

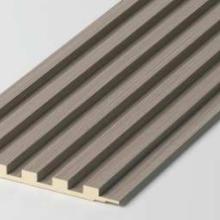

Battens

Our battens are made up of fasade aluminium strips with decorative powder coating in a single matte RAL colour and slats of closed rectangular or square shape.

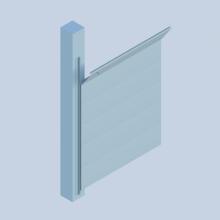

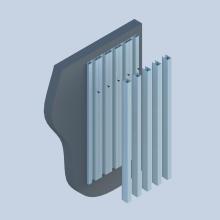

The fastening of the slats to the walls is carried out on a horizontal

aluminium track, using a corner attached from the back side.

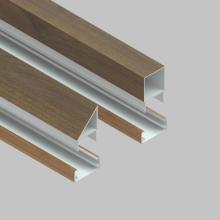

Standard rail sizes:

rail section 75x25mm angle

rail section 38x46mm square

rail section 38x16mm

rail section 150x50mm

rail section 65x16mm

rail section 100x16mm

rail section 25x50mm

cross-section of the rail 50x25mm

cross-section of the rail 50x50mm

rail section 100x50mm

The maximum length of the aluminium lamella is 6500mm

We can also custom make to your specific requirements.

Stages of aluminium batten production:

Stage 1. Manufacturing of aluminium.

Stage 2. Cleaning, painting, priming.

Stage 3. Panel fabrication.

Step 4. Painting AKZO Nobel and baking at 200°C

Stage 5. Sublimation ofcolours (Italian production)

Our entire manufacturing process takes place in our Gold Coast premises, expediting the production process and minimising costs, allowing us to deliver a high quality, affordable product.